Specialised technical services to build a Data Center for a leading Bank Institution

Client: Undisclosed

Services in this project:

- Technical design

- Support for tendering procedure

- Works Supervision and Operational Management

- Assistance to testing

The project called for the construction of four new Data Center Rooms as an extension to the existing ones by making use of the installations already in use on the site.

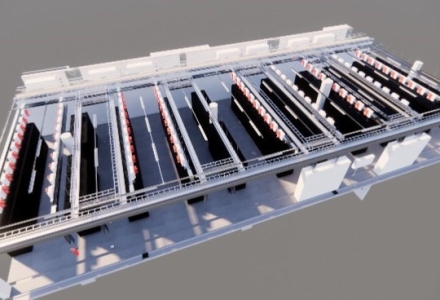

The racks have dimensions of 800x1200x2000mm and have been placed to create functional islands for the compartmentalisation of the central hot aisle and the surrounding chilled environment. The conditioning of the facility is provided by In Row cooling units measuring 300x1200x2000 millimetres, which were installed according to the design layout in an alternating pattern across the cabinets to guarantee an N+2 redundancy for each row.

The creation of the two rooms required the construction of a ventilated wall of concrete blocks to provide the necessary mechanical resistance for the anchoring of other additional equipment, as well as the minimum fire protection requirements necessary to operate the two rooms independently.

The entire hall was fitted with a raised technical floor 35 centimetres high with a load-bearing capacity of approximately 2000 kg/m². To improve fire safety, all structural concrete elements were covered or protected with calcium silicate boards.

Access is gained using a metal ramp with a Keller grating walkway, with separate entrances for people and materials; a masonry compartment with a double door and access badge has been provided for the materials, while a prefabricated semi-circular glass compartment has been installed as a single access point for people. One of the existing entrances was closed to create a new emergency exit, fitted with a steel walkway and stairs to bridge the height difference with the existing floor.

All the new doors meet the REI 120 Italian standard for mechanical resistance, airtightness, and thermal insulation and also have differentiated heights to allow for the passage of people (h=240 cm) and materials (h=270 cm). The doors are also equipped with a badge reader and an electric lock.

The mechanical connections run through a pre-existing duct that connects the central heating station to the current storage room on the second basement level. This solution was implemented after removing old and unnecessary pipework.

The hydronic pipework system is then divided into a main distribution network running at an elevated level at the end of the hall and a secondary distribution network under the floor along the heated corridors to supply the CDZ Series air conditioners. Conversely, the electrical installations are located in the higher section of the room; in fact, from the Low Voltage General Switchboard (LVSB) installed in the adjacent rooms, the power supplies are wired to the busbars, which supply the racks. Metal cable trays for the distribution of services and fiber optic cables were also installed in the upper section. These connect to the existing cable trays in the corridors.

To protect against possible leaks from the hydronic system, a self-levelling layer of a few millimetres was placed under the technical floor to create a slope towards the future water collection drains installed in the ceiling. If a pipe breaks, the water is effectively diverted to the level below to be drained through the existing network.

A Novec gas system provides fire suppression with gas storage cylinders, a pump system and nozzles installed throughout the room. A mechanical ventilation system of sheet metal ducts is installed on the premises.

Lastly, the compartmentalisation of the islands was built with a steel structure and a ceiling made of Plexiglass or polycarbonate panels, raised by roughly 20 centimetres to allow easy movement inside the island, creating a corridor of approximately 2.20 metres in height.

Connect with Our Team

Project data

- Country

- Italy

- Location

- Verona

- Year

- 2021 - ongoing

- Status

- Completed

Other related projects:

- Construction of New Data Center and offices for the client Noovle

- Site adaptation for the Euro HPC Supercomputer

- Engineering design to build a Data Center for the Client Irideos Data Center Italy

- Specialised technical services for the Data Center of the Veneto Region

- Specialised technical services for the Fastweb Data Center

- Engineering design services for the development of a Data Center Campus in the metropolitan area of Milan

L’intera sala è stata pavimentata con pavimento tecnico rialzato di altezza 35 cm e portata di circa 2000 kg/mq e tutti gli elementi strutturali in calcestruzzo sono stati rivestiti o protetti con delle lastre in calcio silicato per aumentare la protezione dal fuoco.

L’ingresso nella sala è possibile grazie ad una rampa metallica con relativo passetto in grigliato Keller e gli accessi alla sala sono differenziati fra materiali e persone; infatti, per i primi è stata predisposta una bussola in muratura con doppia porta e badge di accesso mentre per le persone è stata installata una bussola prefabbricata di tipo semicircolare in vetro per l’accesso singolo. E’ stato chiuso uno degli attuali accessi alla sala per crearne uno nuovo identificato come uscita di sicurezza, munito di passetto e scale in acciaio per colmare la differenza di quota con il pavimento esistente.

Tutte le porte di nuova realizzazione hanno caratteristiche REI 120 e altezze differenziate in modo da consentire il passaggio di persone (h=240 cm) e di materiali (h=270 cm) e sono munite di lettore di badge ed elettro serratura.

Other projects related to this area

-

Lombardy

Lombardy -

Bologna

BolognaSite adaptation for the Euro HPC Supercomputer

-

Milan

MilanEngineering design to build a Data Center for the Client Irideos Data Center Italy

-

Mestre (Venice)

Mestre (Venice)Specialised technical services for the Data Center of the Veneto Region

-

Rome

RomeSpecialised technical services for the Fastweb Data Center

-

Milan

MilanEngineering design services for the development of a Data Center Campus in the metropolitan area of Milan

-

Milan

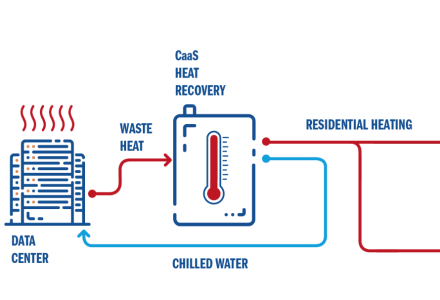

MilanHeat Reuse – Connection to A2A District Heating